| Availability: | |

|---|---|

| Quantity: | |

50T

XLF

VP0004

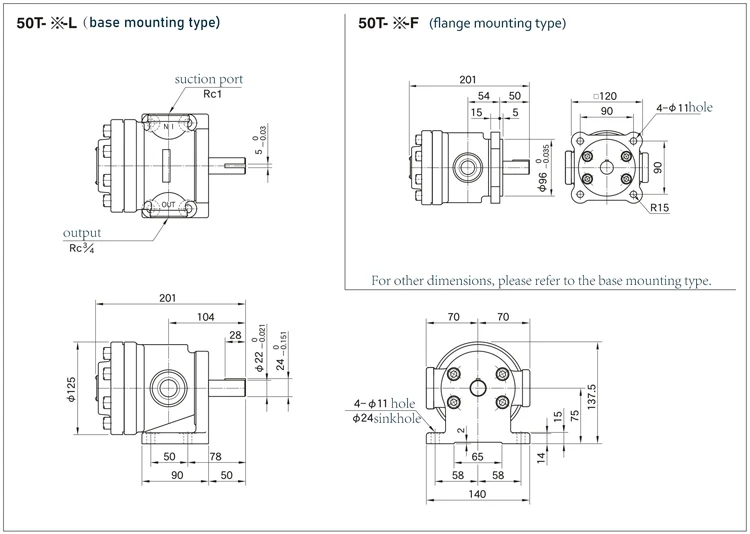

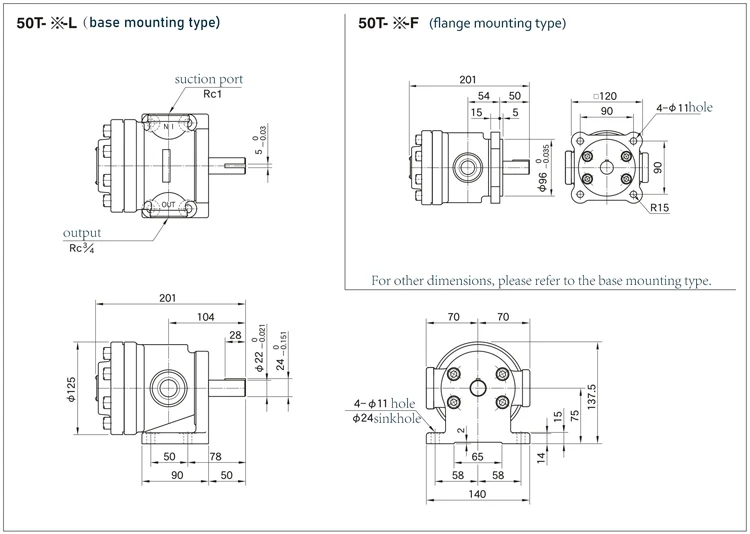

| 50T | —7 | —L | —R | L | —30 |

| Serial Number | nominal displacement cm3/rev | Installation form | turn around | Interface location | Design Number |

| 50T (Threaded connection) 150T (Threaded connection) | 7、12、17、23、26、36 48、61、75、94、116 | F:Flange mounting type L:Base mounting type | Viewed from the shaft extension R:clockwise direction (standard) | Viewed from the shaft extension L:On the left hand side(standard) | 30 40 |

To protect your rights please read the following carefully Pump Start-up Procedure Preparation Prior to Start-up The reservoir and circuit should be clean and free of dirt and debris prior to filling with fluid. Circuit Cleanup The reservoir should be charged with filtered hydraulic fluid. The fluid level should be sufficient to prevent vortexing at the suction connection to the pump inlet. It is good practice to clean the system by flushing and filtering, using an external slave pump. Filling Pump and Removing Air If the pump is mounted above the fluid level, it should be filled with fluid through the outlet port. If the pump is mounted below the fluid level, the pump outlet fitting (or other downstream fitting or plug) can be loosened to allow fluid to displace the air. It may be necessary to loosen the fill cap on the reservoir to allow the fluid to flow freely. When a solid stream of fluid with no observed air begins to drain through the loosened fitting, the fitting should be retightened. An air bleed valve in the outlet circuit is also recommended to remove trapped air. If such a device is used, the pump should be filled with fluid before start-up. In some cases, it may be possible to prime the pump by running the engine starter for five to ten seconds with the throttle and/or ignition switch in the "off" position. It will be necessary to loosen a fitting or plug in the pump outlet to allow air to escape. Pump Start-up All controls should be placed in the neutral position so the pump is unloaded when started. Start the engine and run at low idle. Once the pump is started, it should prime and pump within a few seconds. If it does not, make sure there are no restrictions between the reservoir and the inlet to the pump, and that there are no air leaks in the inlet line and connections. Also, make sure that trapped air can escape from the outlet. Run at low engine idle for approximately five minutes. Then, while observing the reservoir fluid level, operate the implements. Extend all actuators to maximum safe limits to completely fill the system with fluid. Do not run with the fluid level below the "low" limit. Add fluid to the reservoir to bring the fluid to the proper fill level.

| 50T | —7 | —L | —R | L | —30 |

| Serial Number | nominal displacement cm3/rev | Installation form | turn around | Interface location | Design Number |

| 50T (Threaded connection) 150T (Threaded connection) | 7、12、17、23、26、36 48、61、75、94、116 | F:Flange mounting type L:Base mounting type | Viewed from the shaft extension R:clockwise direction (standard) | Viewed from the shaft extension L:On the left hand side(standard) | 30 40 |

To protect your rights please read the following carefully Pump Start-up Procedure Preparation Prior to Start-up The reservoir and circuit should be clean and free of dirt and debris prior to filling with fluid. Circuit Cleanup The reservoir should be charged with filtered hydraulic fluid. The fluid level should be sufficient to prevent vortexing at the suction connection to the pump inlet. It is good practice to clean the system by flushing and filtering, using an external slave pump. Filling Pump and Removing Air If the pump is mounted above the fluid level, it should be filled with fluid through the outlet port. If the pump is mounted below the fluid level, the pump outlet fitting (or other downstream fitting or plug) can be loosened to allow fluid to displace the air. It may be necessary to loosen the fill cap on the reservoir to allow the fluid to flow freely. When a solid stream of fluid with no observed air begins to drain through the loosened fitting, the fitting should be retightened. An air bleed valve in the outlet circuit is also recommended to remove trapped air. If such a device is used, the pump should be filled with fluid before start-up. In some cases, it may be possible to prime the pump by running the engine starter for five to ten seconds with the throttle and/or ignition switch in the "off" position. It will be necessary to loosen a fitting or plug in the pump outlet to allow air to escape. Pump Start-up All controls should be placed in the neutral position so the pump is unloaded when started. Start the engine and run at low idle. Once the pump is started, it should prime and pump within a few seconds. If it does not, make sure there are no restrictions between the reservoir and the inlet to the pump, and that there are no air leaks in the inlet line and connections. Also, make sure that trapped air can escape from the outlet. Run at low engine idle for approximately five minutes. Then, while observing the reservoir fluid level, operate the implements. Extend all actuators to maximum safe limits to completely fill the system with fluid. Do not run with the fluid level below the "low" limit. Add fluid to the reservoir to bring the fluid to the proper fill level.

Address: Shenghua Industrial Park, Xincheng 12 road, Dongxihu District, Wuhan, China

Phone: +86-18908655554

WhatsApp: +86-18908655554

Email: service@xlf-hydraulic.com